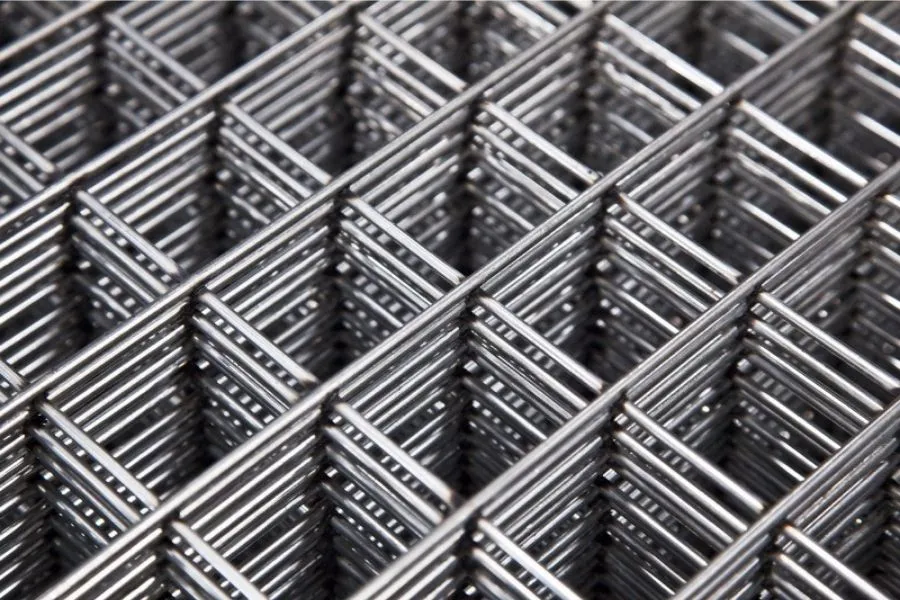

Wire mesh has a versatile structure. That's why there are so many different variations in the global arena. One of the biggest reasons why wire mesh products are preferred so much is that this product has a lot of usage area. It can be produced in woven or welded structure according to the usage area or production type. This affects the pore sizes of the wire mesh and its production in different combinations.

The raw material of wire mesh production is actually metal wires. It is produced using different looms, which means that all metal wires that can be woven can actually be used for the production of mesh wire. Wire diameters of wire mesh to be used as architectural wire mesh and wire mesh wire to be used industrially differ from each other.

The use of wire mesh is mostly used for space separation or for the purpose of lattice knitting. In this case, it is an indication that it is not used only for space separation. Naturally, the multiplicity of usage areas is among the main reasons for its preference.

Used in industrial areas, it is generally used for separating and filtering areas, while it is also used in daily life to prevent insects or create animal fences for garden protection.

At the same time, wire mesh products have recently been used frequently in the fields of architecture and art. Wire mesh is generally produced as a result of the wires being melted, boiled and combined with the weaving process.

It is known that our Estenet brand has been used in many different fields, especially in the building and construction, chemical, food, textile sectors since its establishment.

What Sets Woven Wire Mesh Products Apart?

Woven wire mesh products stand out in the marketplace for several key reasons: versatility, durability, precision manufacturing, customizability, and aesthetic appeal. These attributes not only define the unique selling proposition of woven wire mesh but also highlight why they are preferred across various industries and applications.

The versatility of woven wire mesh is unmatched, capable of serving multiple functions from filtration and screening in industrial settings to creative applications in architectural designs. Its ability to be manufactured in a wide range of mesh sizes and wire diameters allows it to meet specific needs, whether it requires fine meshes for filtration or coarser meshes for structural projects.

Durability is another hallmark of woven wire mesh products, especially those made from materials like stainless steel, which offers exceptional corrosion resistance and strength. This resilience ensures that woven wire mesh can withstand harsh environments and demanding applications, making it a long-term solution for many projects.

Precision manufacturing techniques are employed to produce woven wire mesh, ensuring consistent mesh size and uniformity across the product. This level of precision is critical in applications where exact filtration sizes or specific physical properties are required, such as in the pharmaceutical or food and beverage industries.

Customizability is a significant advantage, as woven wire mesh can be tailored to meet unique project specifications. This includes not just dimensions and materials, but also the type of weave pattern, which can range from simple plain weaves to complex twill and Dutch weaves, offering specific benefits in terms of strength, flexibility, and filtration capabilities.

Lastly, the aesthetic appeal of woven wire mesh cannot be overlooked. Its unique textures and patterns make it a popular choice for decorative applications, including facades, interior partitions, and artwork. The ability to blend functionality with beauty allows designers and architects to use woven wire mesh in innovative ways that enhance the visual impact of their projects.