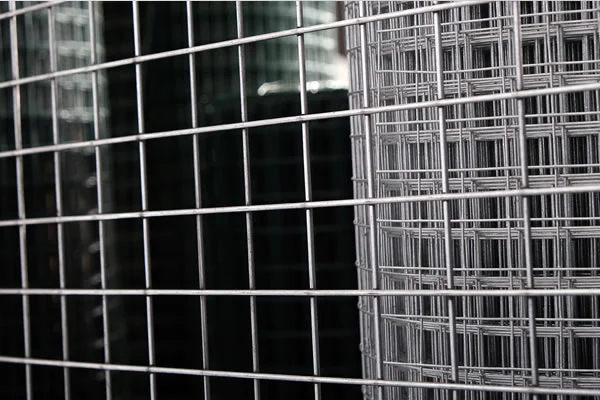

Galvanizing is the coating of steel by immersion in molten zinc at a temperature of 450-455 degrees. Zinc forms a three-phase layer that forms strong bonds with iron. This process allows to extend the service life of metals operating in all external atmospheric conditions, especially against corrosion.

Galvanized wire; It is one of the products obtained by hot dipping in rolling. The zinc is liquefied and the steel wire is immersed in this liquid. Therefore, the wire is galvanized. Galvanized, the specified surface of the wire; It protects against the risk of breakage, rust and damage. Our Estenet brand, which successfully uses its advanced technology in galvanized wire production, reflects its high quality to its galvanized wire product.

Galvanized Wire Features

It is rustproof, indestructible, unbreakable, unbreakable. It is not affected by corrosion. He is durable. It is resistant to conditions such as melting and breaking. Humidity, temperature, pressure etc. not affected by the factors. It is resistant to harsh climatic conditions. It can be of different lengths and thicknesses. It is made by dipping steel wire into liquid zinc. It has a permanent structure.

Galvanized Wire Advantages

It is not damaged by cold, humidity, heat and similar environmental effects. It is suitable for outdoor use. It has a homogeneous structure, has a smooth coating. It preserves its structure for a long time. It is impact resistant. It does not pose a threat to human health and gives a decorative appearance to the place where it is used. Reduces exposure to harmful sun rays. Maintenance costs are low. It is useful in this sense. They show high performance. These wires, which protect the environment from external dangers such as thieves and animals, provide high performance thanks to their robust structure. The process used to coat the wire preserves all parts of the material, including sharp edges and gaps. No industrial coating can provide the same protection as galvanized wire.

Where is galvanized wire used?

Decoration, construction, poultry houses, office terraces, borders, fence manufacturing (especially wall fences), viticulture, greenhouse cultivation, orchards and gardens, green areas, landscaping, barren areas, parks, recreation and picnic areas, factories, construction sites, packaging, automotive You can choose the best galvanized wire models from us for different fields such as We can help you with how you can add value to life by increasing the safety, comfort and aesthetics of your buildings.

Maximizing Durability with Galvanized Wire: A Guide to Enhanced Metal Protection

Galvanized wire stands as a testament to the power of science and technology in extending the lifespan of metal products. Through the process of hot-dip galvanization, steel wire is submerged in molten zinc at temperatures around 450-455 degrees Celsius. This immersion forms a three-phase layer that not only bonds strongly with iron but also provides unparalleled protection against environmental factors. The Estenet brand, leveraging advanced technology in the production of galvanized wire, showcases the pinnacle of quality in this field.

Galvanized wire is renowned for its robustness against corrosion, making it virtually indestructible and rustproof. It maintains its integrity against factors such as humidity, temperature, and pressure, offering resistance to harsh climatic conditions. Available in various lengths and thicknesses, its production involves the steel wire being dipped into liquid zinc, resulting in a permanent structure that's built to last.

The advantages of using galvanized wire are manifold. It remains unaffected by environmental challenges like cold, humidity, and heat, making it ideal for outdoor applications. Its homogeneous structure and smooth coating ensure long-term preservation of its form, while its impact resistance and non-toxicity contribute to both safety and aesthetics. Notably, it also offers protection against harmful sun rays, and due to its low maintenance requirements, it is both cost-effective and environmentally friendly.

Galvanized wire's application spectrum is vast, ranging from decoration and construction to more specialized uses in poultry houses, fence manufacturing, and agriculture. Its utility in enhancing the safety, comfort, and visual appeal of various spaces is undeniable.

Whether it's for vineyards, greenhouses, parks, or even automotive and packaging industries, galvanized wire provides a solution that combines efficiency with performance.